1970 Ford F700

August 2023

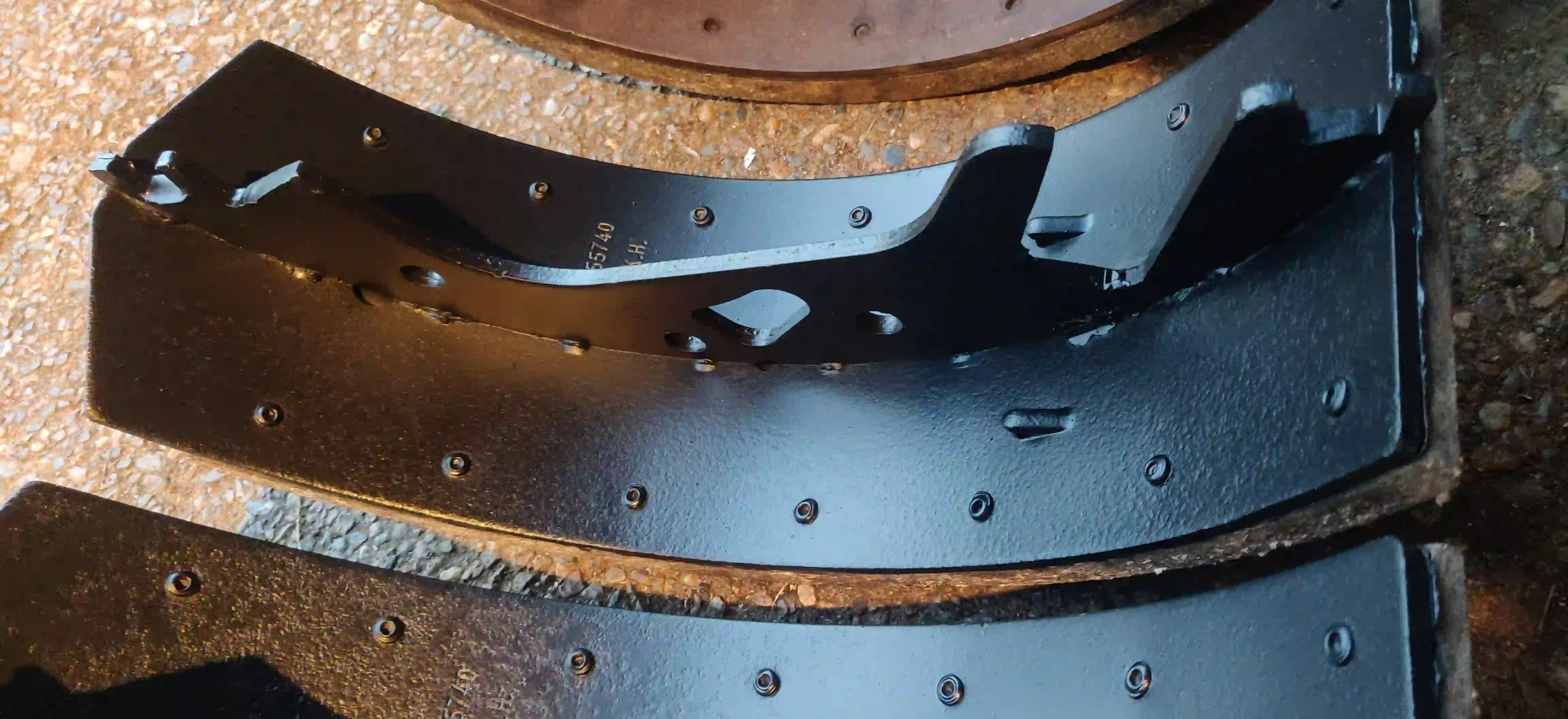

Rusty brake shoes.

Brake shoe after sandblasting.

All the brake shoes have a weak spot where the "brake shoe web slot" presses against the brake shoe backing plate. Some of these weak spots cracked, so I strenghtened them by filling the crack with weld.

After sandblasting and welding, I painted the metal surfaces with black zinc paint. They look good now.

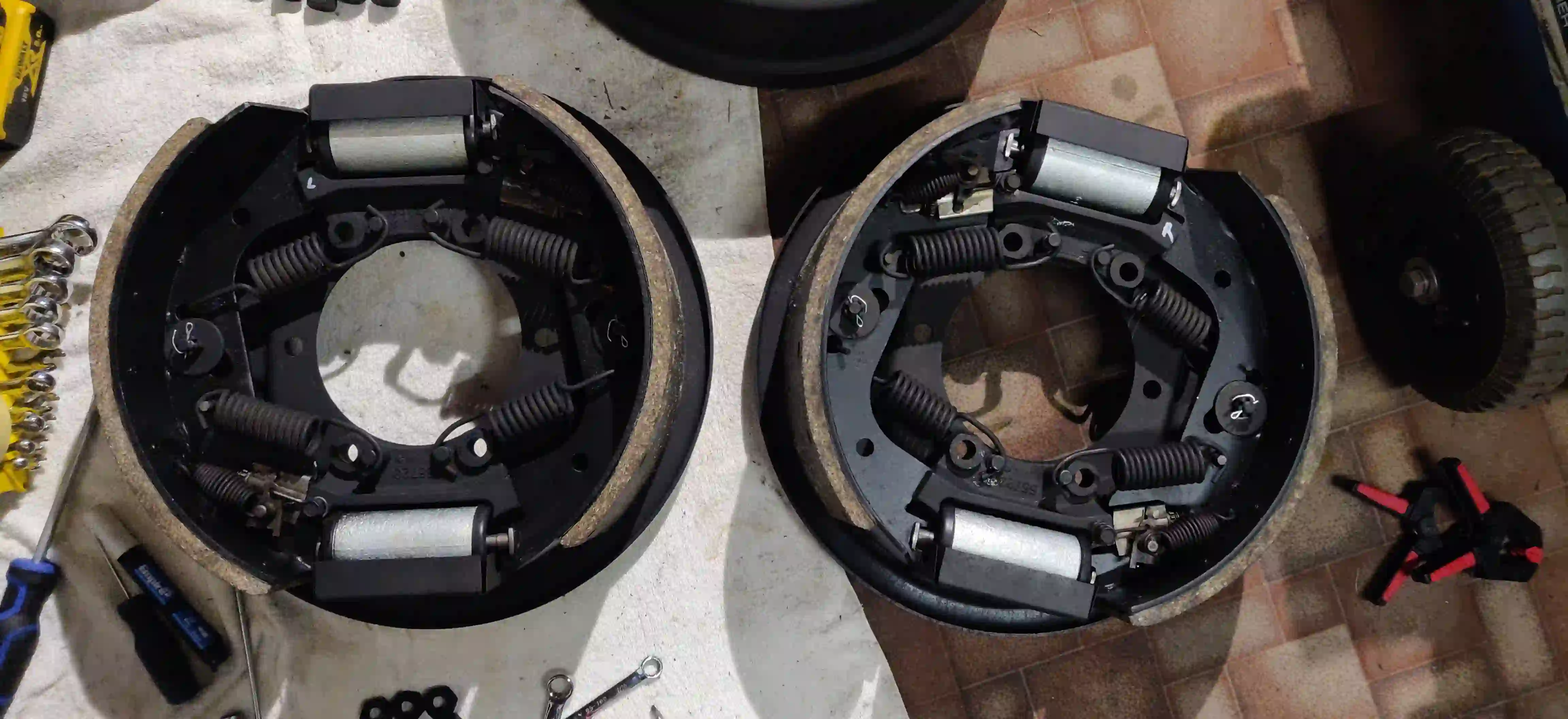

My father and I reassmebled the backing plates. We applied copper-eze anti-seize grease to the threads of the bolts to help prevent corrosion and make the next service easier.

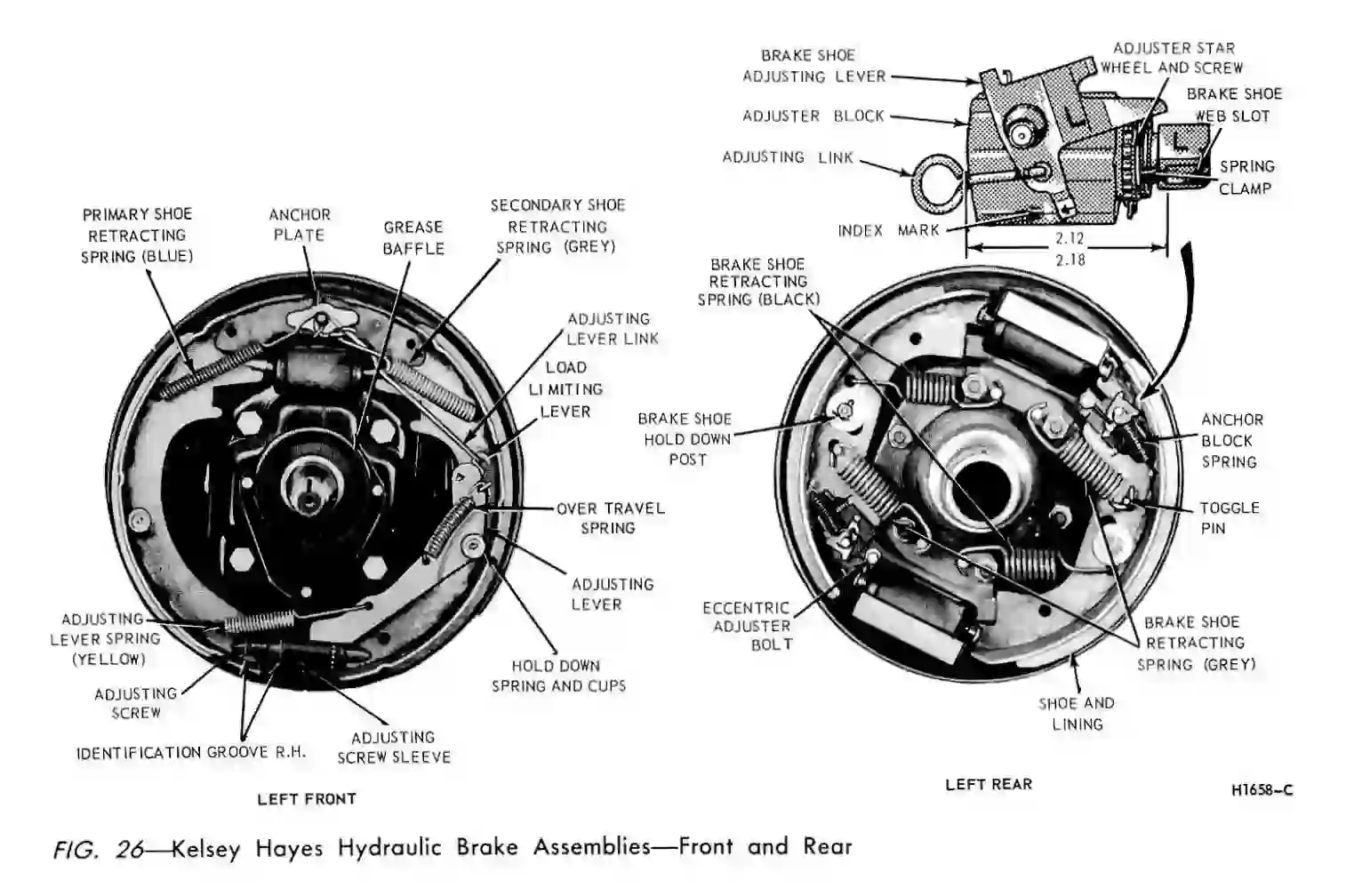

According to the workshop manual, my truck has the Kelsey Hayes braking system installed. We used this photo as a reference when reassembling the backing plate.

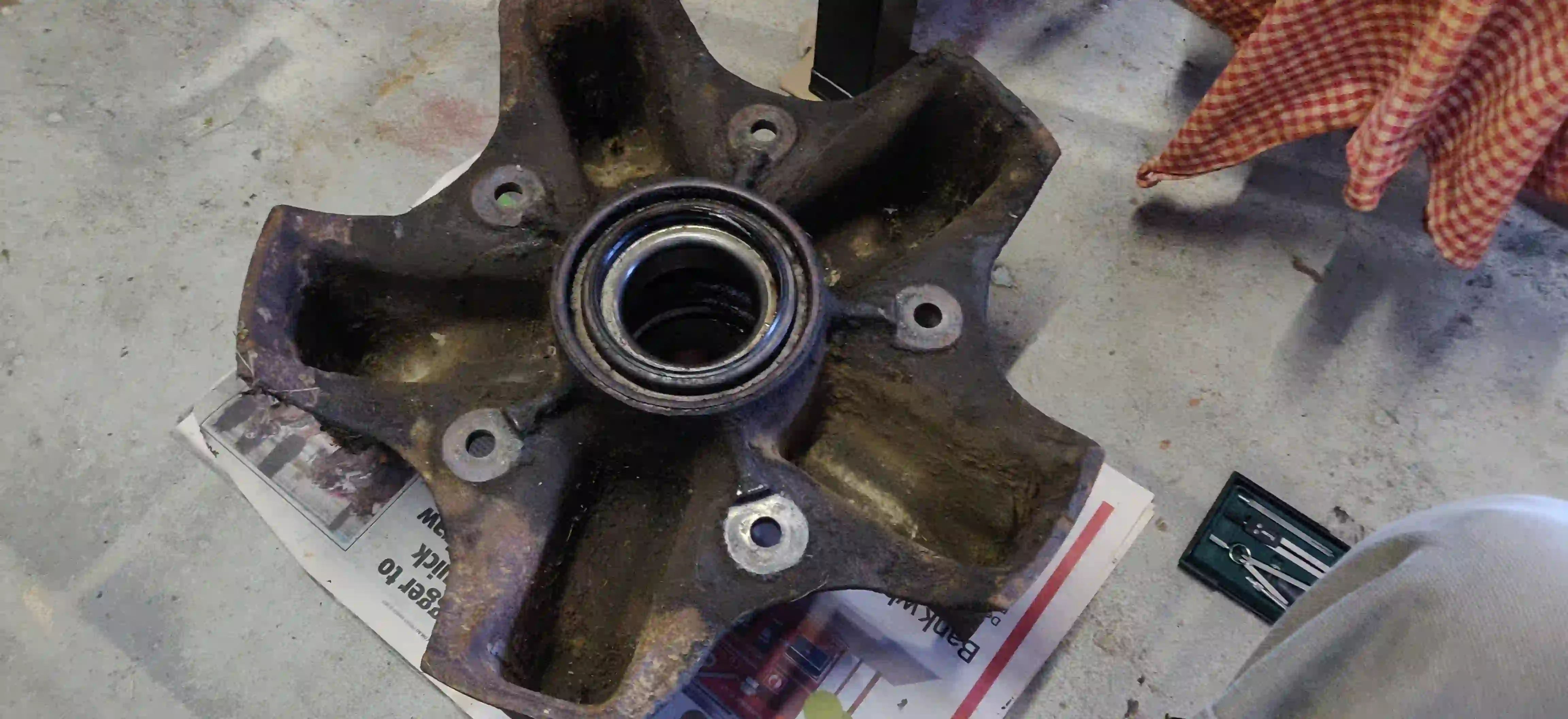

Spider hub. This hub runs on two bearings: an inner and outer bearing.

Outer bearing of the spider hub. Made in Canada, TIMKEN 39590 (Ford 7EQH-1240). The race or cup it sits in is the TIMKEN 39520 (Ford 7EQH-1239). The outer bearing is smaller than the inner bearing.

Inner bearing of the spider hub. Made in Canada, TIMKEN 495AX (Ford 7EQ-1244). The race or cup it sits in is the TIMKEN 493 (Ford B6Q-1243-A).

|

|

|

|

|

|

After buying a new 20-tonne press, I had to fabricate two driving plates of thick steel, one for each bearing race. The outer race (top row) took 2 tonnes to be pressed out, and the inner race (bottom row) took 3. The inner and outer race driving plates have approximate respective diameters of 98.5 and 118.5 mm. Your diameter requirements may vary, due to inevitable machining tolerances and casting imperfections in the factory where the wheel hubs were made.

The inner race (top), inner bearing (middle), and seal (bottom) were all pushed out at once. Seal information: NATIONAL --B B2155BJR | TIMKEN 5089 | Ford DOTZ-1175-E.

.gif)

.gif)